Zogulitsa

Perforated zitsulo Mzere PE chitoliro Kwa mpweya

Kugwiritsa ntchito

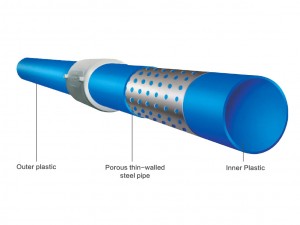

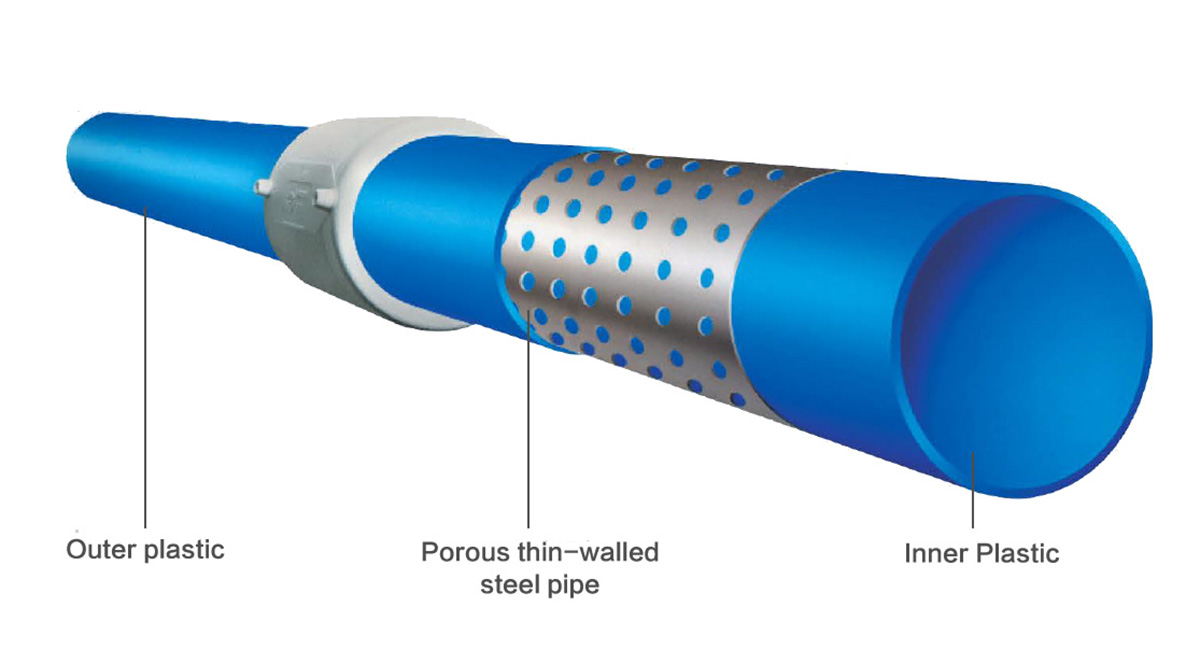

Perforated steel strip polyethylene composite chitoliro amapangidwa ndi ozizira-anagulung'undisa Mzere zitsulo ndi thermoplastics monga zopangira, ndi porous mipope woonda-mipanda zitsulo opangidwa ndi argon arc butt kuwotcherera kapena plasma ozungulira kuwotcherera ntchito monga reinforcements. Zigawo zakunja ndi zamkati zimakhala ndi mbali ziwiri za thermoplastics. Mtundu watsopano wa chitoliro chophatikizika chophatikizika, Chifukwa chowonjezera chowonjezera chachitsulo chokhala ndi mipanda yopyapyala chimakutidwa ndi thermoplastic mosalekeza, chitoliro chophatikizika ichi sichimangogonjetsa zofooka za mipope yachitsulo ndi mapaipi apulasitiki, komanso imakhala ndi kulimba kwa mipope yachitsulo ndi dzimbiri. kukana mapaipi apulasitiki. Ndi njira yothetsera mafakitale a petroleum ndi mankhwala. Ndi payipi yofunikira mwachangu ya mipope yayikulu ndi sing'anga yolimba m'minda yamankhwala, chakudya, migodi, gasi ndi zina. Ndichipambano chosinthika chaukadaulo kuthana ndi payipi yayikulu yomanga ndi kuperekera madzi amtawuni. Ndi mtundu watsopano wa mapaipi ophatikizika mu 21stzaka zana.

Mawonekedwe

Kuchita kwaukhondo

Mlozera waukhondo ndi chitetezo cha chitoliro chophatikizika chachitsulo cha perforated zitsulo zimakwaniritsa zofunikira za GB9687 "Hygienic Standard for Polyethylene Molded Products for Food Packaging" ndi GВ/Т17219 "Safety Evaluation Standard for Drinking Water Distribution Equipment and on Equipment and Protective Equipment". Ndiwolowa m'malo mwa chitoliro cha malata ndi chitoliro chachitsulo.

Khoma lamkati losalala komanso magwiridwe antchito

Khoma lamkati la chitoliro cha chitsulo cha mesh lamba la pulasitiki ndi losalala kwambiri, ndipo kuuma kwathunthu ndi 1/20 yokha ya chitoliro chachitsulo. Mphamvu yotumizira pansi pamikhalidwe yomweyi ndi pafupifupi 30% kuposa ya chitoliro chachitsulo.

Technical Parameters

| Kukula kwatsatanetsatane, kupatuka ndi kukakamizidwa mwadzina: kukwaniritsa zofunikira za Unduna wa Zomangamanga CJ/T181-2003 | |||||

| Mwadzina akunja awiri ndi kupatuka | Mwadzina khoma makulidwe ndi kupatuka | Kuchokera kuzungulira | Kupanikizika mwadzina | Mtengo wocheperako wa S | Utali ndi kupatuka |

| Dn(mm) | Ine (mm) | Mm | Mpa | Mm | mm |

| 50+0.5 0 | 4.0+0.5 9 | 1.0 | 1.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5+0.6 0 | 1.26 | 1.0 | 1.5 | |

| 75+0.7 0 | 5.0+0.7 0 | 1.5 | 1.0 | 1.5 | |

| 90+0.9 0 | 5.5+0.8 0 | 1.8 | 1.0 | 1.5 | |

| 110+1.0 0 | 6.0+0.9 0 | 2.2 | 1.0 | 1.5 | |

| 140+1.1 0 | 8.0+1.0 0 | 2.8 | 1.0 | 2.5 | |

| 160+1.2 0 | 10.0+1.1 0 | 3.2 | 1.0 | 2.5 | |

| 200+1.3 0 | 11.0+1.2 0 | 4.0 | 1.0 | 2.5 | |

| 250+1.4 0 | 12.0+1.3 0 | 5.0 | 0.8 | 3.5 | |

| 315+1.6 0 | 13.0+1.4 0 | 6.3 | 0.8 | 3.5 | |

| 400+1.6 0 | 15.0+1.5 0 | 8.0 | 0.8 | 3.5 | |

| 500+1.7 0 | 16.0+1.6 0 | 10.0 | 0.6 | 4.0 | |

| 630+1.8 0 | 17.0+1.7 0 | 12.3 | 0.6 | 4.0 | |

| Zindikirani: Kuthamanga kwadzina kwa chitoliro chophatikizika ndiko kuthamanga kwakukulu komwe kumaloledwa kuti chitoliro chinyamule madzi pa 20 ° С. Ngati kutentha kumasintha, kuthamanga kwa ntchito kuyenera kukonzedwa molingana ndi kutentha kwa kutentha kwa zipangizo zosiyanasiyana. Mtengo wa S: mtunda wochokera kumtunda wakunja kwa kulimbikitsa mpaka kunja kwa chitoliro. | |||||

| Zofunikira zakuthupi ndi zamakina | ||

| Ntchito | Kachitidwe | |

| Kulimba kwa mphete, KN/m2 | > 8 | |

| Kutsika kwautali (110 ° С, sungani 1h) | <0.3% | |

| Mayeso a Hydraulic | Kutentha: 20 ° С; Nthawi: 1h; Kupanikizika mwadzina x2 | Osasweka |

| Kutentha: 80 ° С; Nthawi: 165h; Kupanikizika: Kuthamanga mwadzina x2x0.71 (kuchepetsa factor) | ||

| Kuphulika kwa kuthamanga kwa mayeso | Kutentha: 20 ° С, kuthamanga kwapang'onopang'ono≥kuthamanga mwadzina x3.0 | Kuphulika |

| Nthawi yolowetsa oxidation (200 ° С), min | >20 | |

| Imakana kukulitsa kupsinjika kwakanthawi (80°С, 4.0Mpa)/h | > 1000 | |

| Kukana kwanyengo (chitoliro chikalandira≥3.5GJ/m2ukalamba mphamvu) | Kukwaniritsa zofunikira za zinthu 2,3 ndi 4 mu tebulo ili, ndipo mutha kukhalabe ndi ntchito yabwino yowotcherera | |